Growing global demand for sustainable agriculture is driving scientists to find smarter ways to handle livestock waste. A new study by Xiaofei Ge and colleagues at China Agricultural University brings artificial intelligence into the mix.

The team used machine learning to predict the destiny of phosphorus—one of agriculture’s most precious but polluting nutrients—through treatment of swine manure. The outcome holds potential for a future when farm waste is recycled as a renewable resource instead of an environmental pollutant.

Animal agriculture produces humongous amounts of manure. Unless handled properly, this runoff will flow into streams and pollute ecosystems and jeopardize public health. But the same waste holds essential nutrients for agriculture, including carbon, nitrogen, and phosphorus. The issue is to reclaim them without further harm.

Phosphorus, as it turns out, is both critical and dangerous. It drives plant growth but is also a limited material. When it is dumped into lakes and rivers, it causes poisonous algal blooms that suffocate aquatic life. “Livestock manure contains massive amounts of phosphorus that are a blessing and a curse,” said Ge. “If they are discharged into the environment, they can contaminate water and land. But if they are reclaimed properly, they can be used as fertilizer to nourish sustainable agriculture.”

The research looked at how hydrothermal treatment, a technique involving using energy to heat pressure-wet biomass, can convert manure into two products: a nutrient-rich solid known as hydrochar and a liquid waste byproduct. Hydrothermal treatment isn’t as conventional as composting or drying and doesn’t require pre-drying, nor does it recycle nutrients as well as these methods do. But it has always been challenging to predict precisely where phosphorus goes during the process.

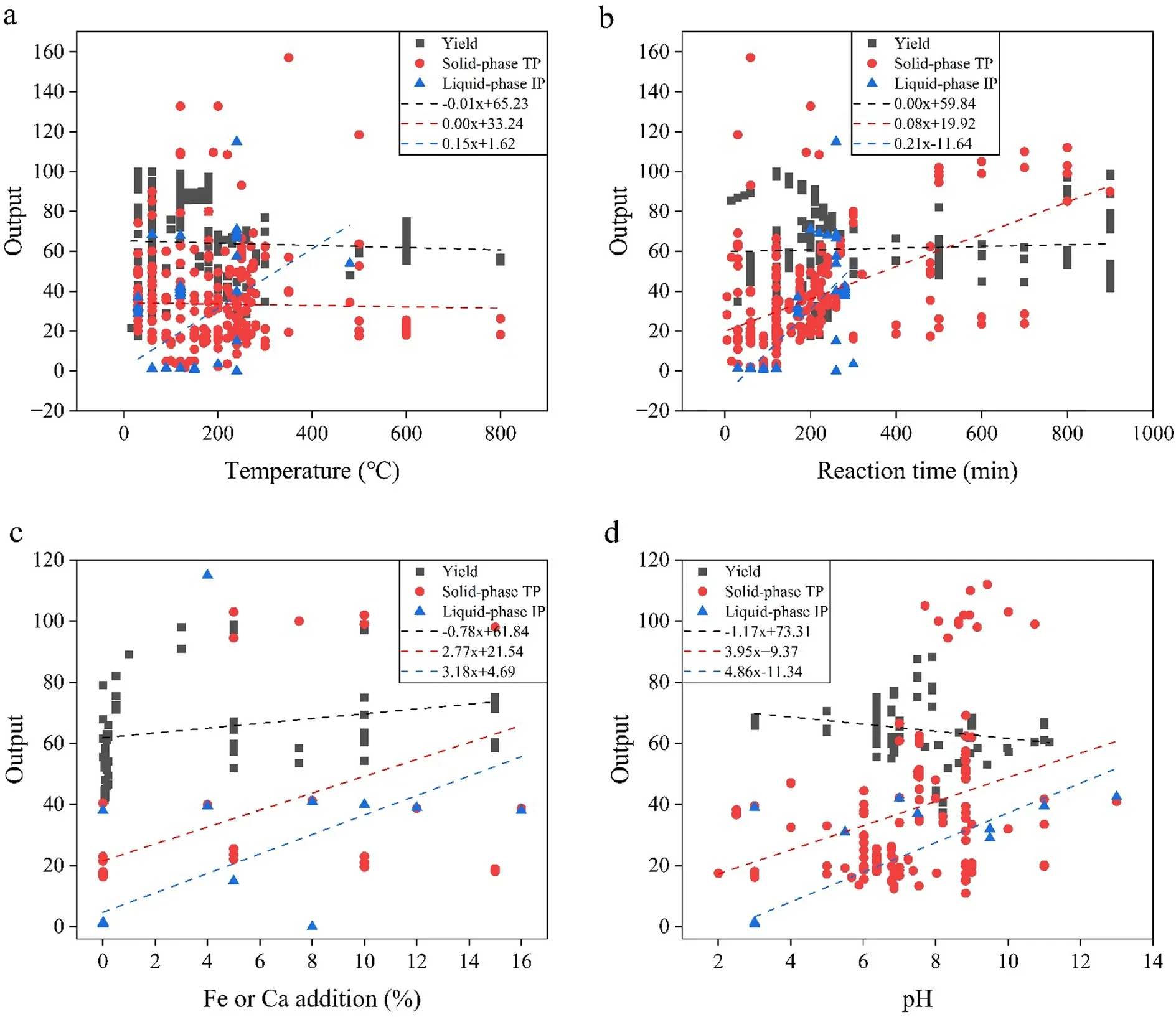

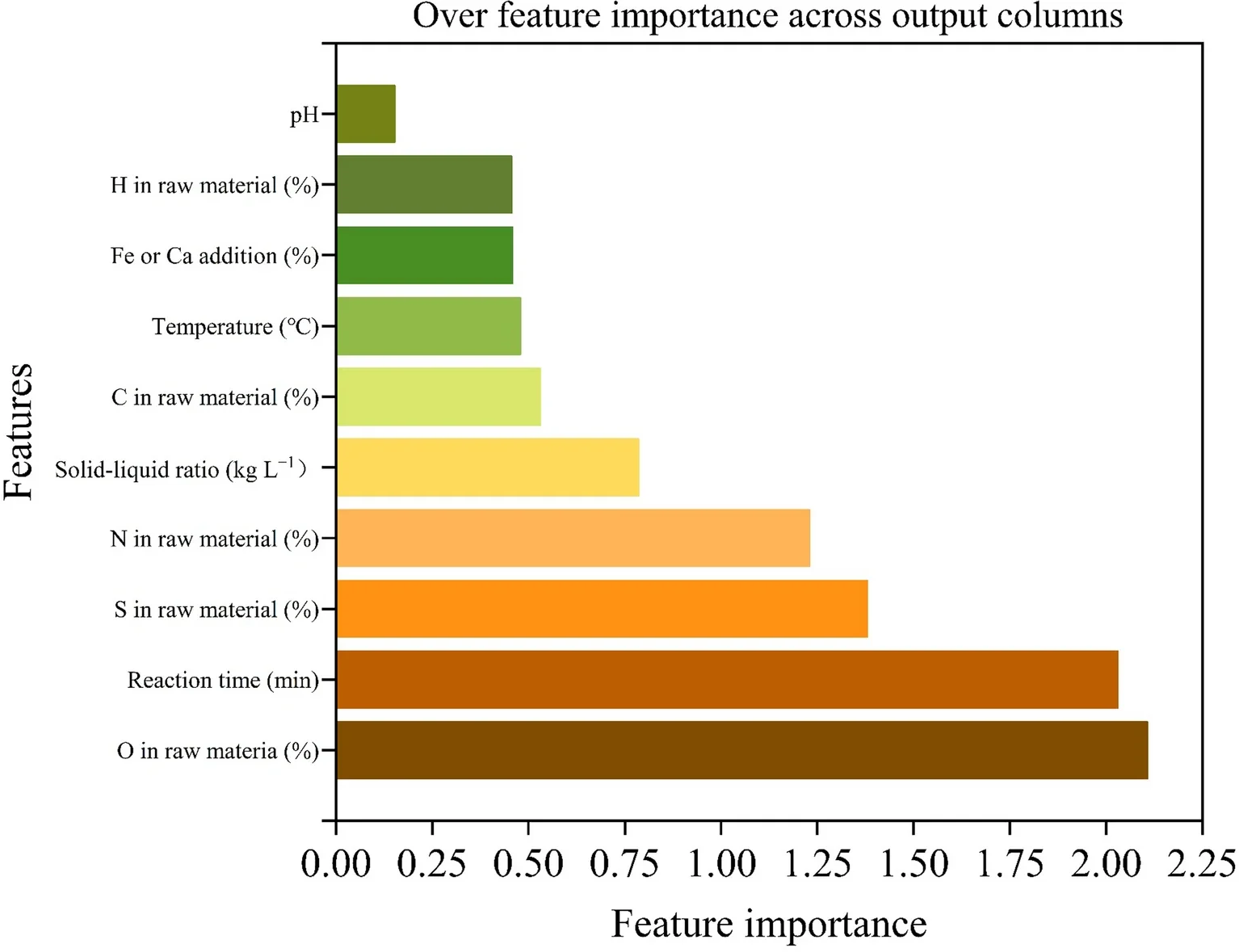

To determine that, Ge’s team applied three machine learning models—XGBoost, Decision Tree, and Random Forest—to forecast how phosphorus divides between the liquid and solid phases based on various conditions. The team trained the models using a dataset of 423 experiments collected from past studies, as well as 32 new experiments that they performed. The data included factors such as reaction temperature, time, pH, and iron and calcium ion concentration.

Among models, XGBoost was the most accurate. It was almost perfectly accurate in predicting phosphorus distribution, particularly when determining inorganic phosphorus levels in the liquid. That indicated the team could make predictions about how to optimize treatment conditions to achieve maximum phosphorus recovery without having to conduct an infinite number of lab tests.

The machine learning models uncovered trends that could potentially alter waste management practices. The composition of the manure—i.e., its oxygen content—was more crucial than time or temperature in determining phosphorus outcomes. However, reaction time was greater than temperature in importance as an influence on operations.

The study found that the higher the temperature, the more phosphorus was captured in the hydrochar and less in the liquid, which eliminated water contamination chances. In very acidic or alkaline conditions, phosphorus was very sensitive to even minute pH variations. Under acidic conditions, it favored the dissolution of phosphorus and alkaline conditions favored its retention in the solid form.

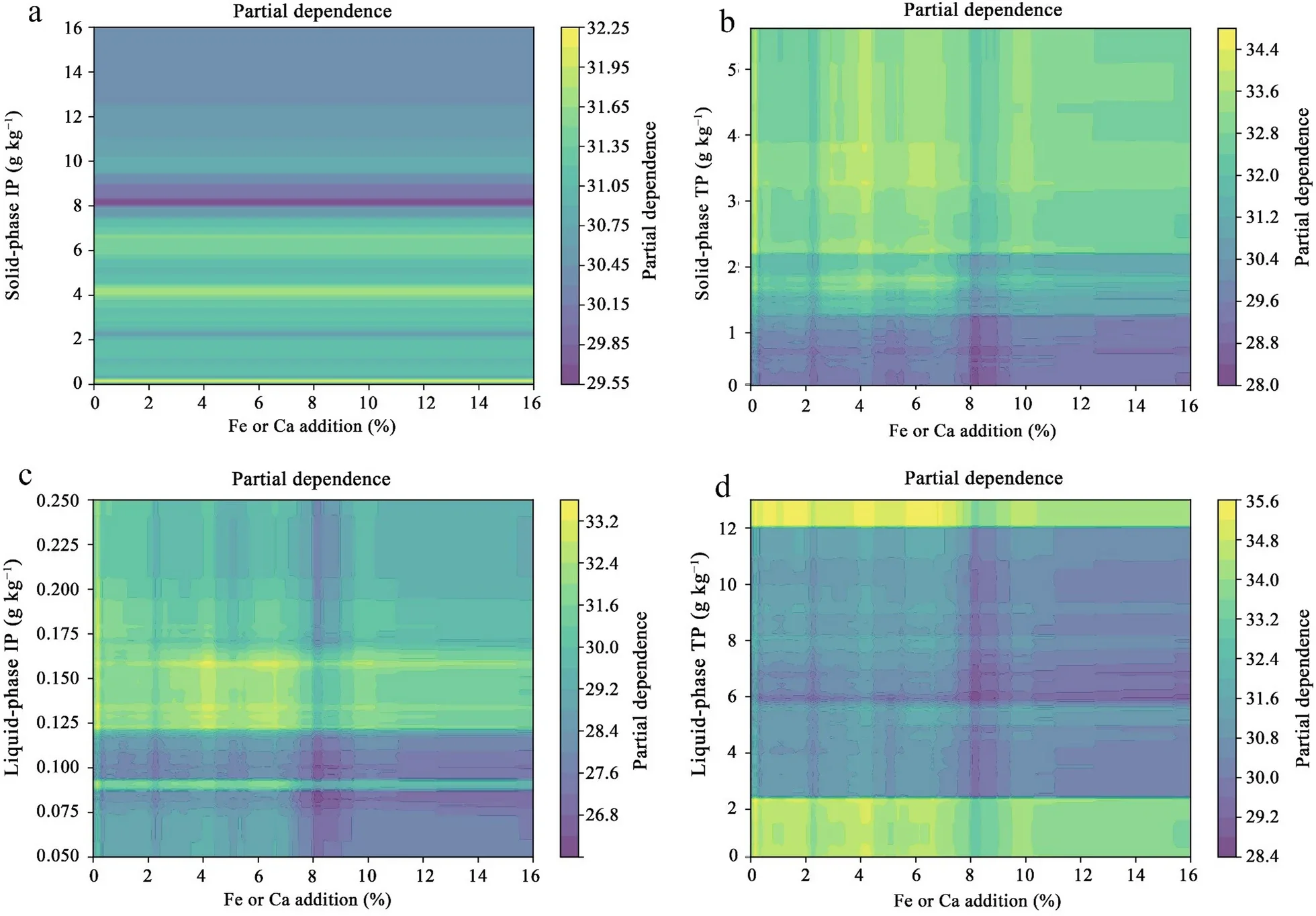

The introduction of iron and calcium ions proved especially beneficial. These metals triggered the precipitation of phosphorus into hydrochar, stabilizing and making it simpler to recycle as fertilizer. “Our findings indicate that machine learning can be utilized to develop more clever waste treatment plans,” reported Sabry M. Shaheen of the University of Wuppertal, a co-corresponding author on the paper. “This has tremendous implications for sustainable agriculture, conservation of the environment, and recovery of resources.”

To verify their model, researchers conducted actual hydrothermal experiments in the field using swine manure from a local pig farm near Beijing. Temperature, reaction time, and iron and calcium ion concentrations were varied. When comparing predicted versus observed results, XGBoost predictions were well-matched with real phosphorus content in solid and liquid phases.

Chemical analysis showed otherwise. Using advanced equipment such as phosphorus nuclear magnetic resonance and X-ray diffraction, the researchers found that with more extreme conditions, phosphorus compounds were more stable and homogenous forms. Metal ions helped in the transformation of organic phosphorus to inorganic forms that were able to form strongly with calcium or iron and embed them within the solid hydrochar.

As the intensity of reaction increased, crystalline structures in hydrochar collapsed and succumbed to more amorphous compounds. This indicated that directions were shifting towards forms that are easier to recycle and reduce leaching into the environment.

This synergy of artificial intelligence and environmental engineering holds the promise to revolutionize how waste treatment plants and farms process organic byproducts. Not relying on error-prone trial experiments, operators can project how to modulate temperature, pH, or reaction time to provide desired outcomes. Operators can decide whether to optimize phosphorus in hydrochar for fertilizer application or lower it in the liquid to prevent runoff.

The authors state that while the model is efficient, it must be calibrated for local conditions since manure composition is not the same in every region and farm. Modification of the method to suit different kinds of waste and making predictions more accurate over broader sets of data are what future studies will cover.

With the integration of hydrothermal treatment and machine learning, this research provides a pathway towards sustainable nutrient recovery. Machine learning can be implemented in waste treatment plants and farms to improve processes, recover valuable phosphorus, and prevent environmental harm.

This technology not only guarantees circular agriculture but also meets global carbon-neutrality and resource conservation targets.

Essentially, recycling manure into usable, nutrient-rich products would aid in closing the loop between agriculture and sustainability.

Research findings are available online in the journal Springer Nature Link.

Like these kind of feel good stories? Get The Brighter Side of News’ newsletter.

The post Scientists use AI to sustainably transform livestock waste into fertilizer appeared first on The Brighter Side of News.

Leave a comment

You must be logged in to post a comment.